10 - 15 m / min Forming Speed Window Frame roll forming machinery Drived by Chain

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

10 - 15 m / min Forming Speed Win

Quick details

| After-sales Service Provided: | Engineers available to service machinery overseas | Usage: | building | Control system: | PLC |

| Name: | Metal door frame roll forming machine line | Machine size: | 11m*1.0m*1.5m | Machine color: | as require |

| Machine weight: | 4tons | Cutting type: | hydraulic | Driven type: | chain |

| Size of container: | 40GP | Life long: | 10years |

Techincal description

A. Manual decoiler

| 1 | Capacity | 5tons |

| 2 | Loading width | MAX 1500mm |

| 3 | Coil inner diameter | 450-600mm |

B. Main roll forming

| 1 | Main motor power | 5kw |

| 2 | Drive | 1''Chain |

| 3 | Main shaft diameter | ¢80mm |

| 4 | Shaft material | 45#forge steel after treatment |

| 5 | Roller material |

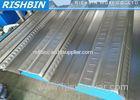

45# steel polished and coated with chrome HRC55-60° chrome coated 0.05mm |

| 6 | Roll station | 16groups |

| 7 | Raw material | 0.3-1.0mm |

| 8 | Working speed | 10m--15m/min |

| 9 | Voltage | 380v,380v,50hz |

C Cutting device

| 1 | Cutting | Hydraulic cutting |

| 2 | Hydraulic power | 7.5KW |

| 3 | Blade material | Cr12,quenched 55°-60°C |

| 4 | Working pressure | 16mpa |

| 5 | Cutting tolerance | +/- 2mm |

D Punching

| 1 | Hydraulic punching AFTER roll forming | |

| 2 | Power | 7.5kw |

E Control system

| 1 | Type | PLC Frequency Control System with touch screen |

| 2 | PLC Brand | Japan Panasonic |

| 3 | Encoder Brand | Omron |

| 4 | Length Error | ±2mm |

Working flow

Decoiler-----feeding----- leveling and guiding ------roll forming ------ punching-----cutting----output table

Machine components

|

No. |

Name |

Qty. |

|

1. |

De-coiler |

1 Set |

|

2. |

Feeding and Guiding Device |

1 Set |

|

RISHBIN WUXI COMPANY [China (Mainland)]

Business Type:Manufacturer |