Automatic Control C & Z Purlin Roll Forming Machine with 6 Stations for Structural Steel

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Quick Detail<

Quick Detail

| 1.Dead weight is very light. The section performance in unit weight is excellent. For same area, steel quantity can be reduced, lowering the material costs. |

| 2.It is of high strength. It can be closely connected, increasing the bearing capacity of the structure. |

| 3. It is easy to install. It can be tailor made on large quantity. Digital scale, machine-made drilling and removing rust are finished in workshop. It can be installed once it is transported to the worksite. |

| 4.Smooth surface, precise size, excellent rust-resistance property and long-term durability. With the advantage of Cee & Zee purlin, they are widely used as the supporter of roof and wall in large-scale and mid-scale construction, such as factory, warehouse, garage, exhibition center, cinema, theatre, garden in steel structure industry and so on. |

Specifications

|

C_Z Purlin roll forming machine Specification |

|

|

Flattening equipment Roller stations |

6 Stations |

|

Punching machine with moulds Capacity |

40T |

|

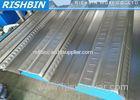

Roll Formed Profile Type: |

C-Z Purline profiles |

|

Line structure |

Portal-type frame style: A3 steel |

|

Forming Roller Stations: |

20 Stations |

|

Forming Roller shaft: |

φ58mm, 40Cr, quenching, heat treatment |

|

Forming rollers |

GCr15, quenching, hardness HRC58-62º |

|

Forming Speed: |

15 meters / min |

|

Main motor: |

30kw |

|

Hydraulic station motor |

5.5kw |

|

feed material thickness: |

(1-3) mm× L |

|

Suitable raw material: |

Q235A galvanized steel sheet |

|

Driving mode: |

Chain driven and gear box transmission is available |

|

Auxiliary rollers station |

5-11 stations |

|

Material of Roller: |

40Cr |

|

Cutting mode: |

automatic punching cutting style , holes Punching Before roll-formed |

|

Blade material: |

Cr12, quenching and treating |

|

Cutting length Tolerance |

3mm |

|

Control mode |

PLC |

|

Line speed |

Adjusted by Frequency Inverter |

|

Power: |

380V/3ph/50Hz or according to the buyer's requirement |

|

Run-out table mode: |

roller style |

|

Line dimension: |

14000mmx 1400mm x 1200mm |

Description

Automatic C-Z purlin changeable machine components:

This whole line is consisted of de-coiler (mainly consists of un-coiler and its base), gearing rigging, roll stand and main machine, pressuring system, cutting equipment, hydraulic system, control system, and product supporter, PLC control system, etc.

Applications

PURLINS, both C and Z, are available in various sizes rolled to any length. They can be ordered plain or with holes pre-punched, as per standard end punching shown below, or punched to any layout required. The standard maximum length for delivery of purlins is 12 meters. Greater length than 12 meters are obtainable but require special delivery vehicles.

Competitive Advantage

We can send the best solution and design different style C & Z Purlin roll forming machine according to client’s requirements, such as holes punched after profile roll formed, or pre- punched, etc. We can do a custom roll forming machine, i.e. we can design the machine according to your specification and profile drawing. Complex questions will be simple here.

Further details, pls contact with us!

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

RISHBIN WUXI COMPANY [China (Mainland)]

Business Type:Manufacturer

City: Wuxi

Province/State: Jiangsu

Country/Region: China (Mainland)