High Frequency C Z Purlin Roll Forming Machines for Steel Structure

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

High Frequency C Z Purlin Roll Forming Machines for Steel Structure

Details Of Roll Forming Main Machine

- Material of roller:GCr15,quenched

- Material of main shaft:45#forge steel

- Main motor:15KW

- Hydraulic power:7.5KW

- Working speed:15m/min

- Forming stations:18 stations

- Control system:PLC Panasonic

- Transmission:by chains 1.2 inch double time

- Main dimension:11000mm*1400mm*1400mm(L,W,H)

- Total weight:14000KG

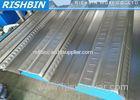

Production Characteristic and Use

This kind of machine can produce C , Z two profiles, through the exchange side of the roller up and down position to achieve C , Z purlin conversion , just need about half an hour to achieve saving time. This machine also can automatically adjust roller horizontal distance to achieve C or Z purlins pf the width with high precision , but also save time to increase production.

Control Panel (PLC Panasonic)

- Automatic length and quantity measurement

- Tolerance of length: 3m+/- 1.5mm

- Computer used to control length and quantity,the machine will automatically cut to length and stop when required quantity is achieved.

- Control panel:button-type switch and touch screen

- The program should be can set 5 different measure and quantity

- The picture of control panel

The Progress Of Punching And Cutting

- Material of punching mold: Cr12 HRC 58-62

- Punching with hydraulic drive

- This machine with 2 sets punching system

1.punching at end-wise controlled by PLC control system

2.punching at broad-wise adjusted by manual

- Material of cutting blade: CR12with heat treatment

- Hydraulic Cutting before forming: Cut the sheet before roll forming to required length

- Cutting motion: The main machine automatically doesn't stop and the continue punching and cutting .

Introduction Of This Machine

- This kind of machine can produce C,Z two profiles,through the exchange side of the roller up and down position to achieve saving time.

- This machine also can automatically adjust roller horizontal distance to achieve C or Z purlins of the width with high precision,but also save time to increase production.

- We adopt the shape-steel structure and process as a whole after welding for this machine.

- It has the ability of strong loading,stable operation,low noise and high efficiency when running the machine.

- we adopt the automatic length-fixed forming and cutting to guarantee the length to be precise and the finished product clear without deforming .

Main Compositions

- Hydraulic Decoiler......................................1unit

- Straightening...............................................1unit

- Roll Forming Machine.................................1unit

- PLC Control System....................................1unit

- Hydraulic Pressing&Cutting.........................1unit

- Hydraulic Station..........................................1unit

- Production Out Table....................................2unit

Noted:All the parameters can be changed as the customer's requirement.

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

RISHBIN WUXI COMPANY [China (Mainland)]

Business Type:Manufacturer

City: Wuxi

Province/State: Jiangsu

Country/Region: China (Mainland)