Roof Batten OMEGA Shape Steel Frame Roll Forming Machine with 5.5 KW Main Power

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Roof Batten OMEGA Shape Steel Frame Roll Forming Machine with 5.5 KW Main Power

<

Roof Batten OMEGA Shape Steel Frame Roll Forming Machine with 5.5 KW Main Power

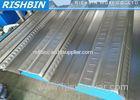

Main Technical Specifications of OMEGA Shape Roll Forming Machine

- Production material: thickness 1.0mm, galvanized steel,

- Forming speed: 15M/min

- 1 station for sheet metal delivering

- 9 stations for roll forming

- Roller material: SCM4 with heat treatment and hard chrome-plated HRC60

- Shaft material:S45C quenched and tempered after finishing treatment

- Material of punching mould: SKD11 with heat treatment

- Shearing blade: material: SKD11 with heat treatment(HRC60), hydraulic operated

- Shaft diameter:φ60mm

- Run-out table: roller type.

- Main motor power: 5.5KW

- Power of hydraulic station: 3.5KW

- Electronic controlling system: full-frequency PLC controlling system

- Holes punching: inline pre holes punching

- Cutting: post cutting with hydraulic driving

Main Parts of OMG Roll Forming Machine

|

NO. |

Name |

Unit |

Qty |

|

1 |

Roll Forming Main Machine |

Set |

1 |

|

2 |

Hydraulic/Manual decoiler |

Set |

1 |

|

3 |

PLC Control System |

Set |

1 |

|

4 |

Hydraulic Punching Device |

Set |

1 |

|

5 |

Hydraulic Cutting Device |

Set |

1 |

|

6 |

Hydraulic Station |

Set |

1 |

|

7 |

Manual Out Table |

Set |

2 |

Structure of OMG Roll Forming Machine

This roll forming machine consists of non-power uncoiler, driven transmission, forming rollers, mainframe (including guiding platform), inline hydraulic holes punching system, two sets of punching moulds for two different sets of holes, hydraulic cutting device, hydraulic station, electric controller and stacker.

Working Process

Coiler loading → inline hydraulic holes punching → feeding-in with adjustable rollers guiding (metal sheet is guided into the first forming station) → rolling & forming → hydraulic cutting → stacker running out

Profile Photos

&nbs

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

RISHBIN WUXI COMPANY [China (Mainland)]

Business Type:Manufacturer

City: Wuxi

Province/State: Jiangsu

Country/Region: China (Mainland)