PLC Control Light Gauge Steel Track Channel Roll Forming Machine 5.5 kw

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

PLC Control Light Gauge Steel Track Chann

PLC Control Light Gauge Steel Track Channel Roll Forming Machine 5.5 kw

Quick Details

| Suitable material thickness: | 0.4-1.2mm |

HMI used in track roll forming machine: |

Panasonic |

| After-sales Service Provided: |

Engineers available to service machinery overseas |

PLC used in track roll forming machine: |

Panasonic |

| Encoder: | Omron | drywall track profile: | as per required |

| Roll forming speed: | 15m/min or 30m/min | Cutting method: |

mould cut, hydraulic driven |

Description of Drywall Track Roll Forming Machine

This kind of machine is PLC control, automatic forming & cutting. The drywall track profile can be as per required.

Main Technical Data of Drywall Track Roll Forming Machine

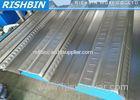

1: Suitable material: galvanized steel, 0.6-1.25mm

2: Forming speed: 12~15m/min (excluding cutting)

3: Steps of rollers: 10 stations

4: Power of main driven motor: 5.5kw

5: Power of hydraulic station motor: 3kW

6: Hydraulic power: 12MPa

7: Cutting type: hydraulic mould cut, stop-to-cut

8: Cut-to-length tolerance: less than +/-1.5mm

9: Control system: PLC control, touch screen, inverter and encoder imported from Japan

Main Parts of Drywall Track Roll Forming Machine

1: Double-head mechanical expansion decoiler: outdiameter 1000mm, max loding capacity

1000kg (each head)

2: Driving system: Cycloid Pin-wheel reducer, gear drive, wire-cut steel stands.

3: Material of rollers: 45# forging steel, rigid chrome coated

Material of shafts: 45# steel, adjusted, diameter 65mm

Material of mould cutting blades: Cr12, quenched HRC 58-62

4: Material of machine base: whole-body welded.

5: Manual run-out rack: 1.5 meters long

Drywall Track Roll Forming Machine

1 PLC control

2 HMI operation

3 Auto form and cut

4 Speed:15m/min or 30m/min,two options

Sample Drawing

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

RISHBIN WUXI COMPANY [China (Mainland)]

Business Type:Manufacturer

City: Wuxi

Province/State: Jiangsu

Country/Region: China (Mainland)