Automatically 18 Rollers Door Frame Roll Forming Machine with Hydraulic Mold Cutting

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Automatically 18 Rollers Door Frame Roll

Automatically 18 Rollers Door Frame Roll Forming Machine with Hydraulic Mold Cutting

Quick Detail:

1. Processing Material colored steel plate, galvanized plate, or aluminum plate

2. Thickness of sheet Processing thickness of plate: ≤1.5mm

3. Equipment operation Automatically

4. Voltage according to customers request

5. Productivity 10-15 m/min

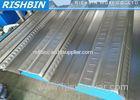

6. Material of Rollers Cr15

7. Material of shafts 40Cr

8. Diameter of shafts 62mm

9. Number of rollers 18 rollers

10. Dimensions( main structure) 15.8*0.8*1.1m

11. Working accuracy 10m±2mm

12. Roller fixer Guide column or Wall Board

13. Frame 350H steel

14. Cutting System Flying saw or Hydraulic mold Cutting

Description:

Composition of machine

Roll forming main machine…………… ................ 1 unit

Manual Un coiler……………………………………… 1 unit

Control panel…………………………………………..1 unit

Hydraulic station…………………………………… …1 unit

Manual out table……………………… ……………….2 unit

Applications:

Door Frame Machine can rollform different kinds metal door or window frames, reinforced, fire stop doors,

etc. The punching also can be designed according to your needs. After roll formed by this roll forming

machine, the surface will be very smooth and beautiful without any scratch on surface. We can design the

machine according to your specification and profile drawing.

Specifications:

| Material spec | colored steel sheet |

| Range of Thickness | 0.3--2 mm |

| roller station | 13 station |

| Voltage | 380V50Hz3phases |

| Level and measure | automatic |

| OD of roller | 50mm |