IBR Corrugated Sheet / Trapezoidal Roof Panel Roll Forming Machine for Roof Sheet

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

IBR Corrugated Sheet / Trapezoidal Roof Panel Roll Forming Machine for Roof Sheet <span

IBR Corrugated Sheet / Trapezoidal Roof Panel Roll Forming Machine for Roof Sheet

Specifications of IBR Corrugated Sheet / Trapezoidal Roof Panel Roll Forming Machine

| Product Name | Item | Description |

| IBR Corrugated Sheet / Trapezoidal Roof Panel Roll Forming Machine | Coil width | Depend on your profiles |

| Working speed | 12-15m/min | |

| Roll station | about 16 - 24 stations | |

| Material of roller | Grade 45 steel, polished and coated with chrome | |

| Material of main shaft | 45 steel | |

| Diameter roller | 70mm | |

| Main power | 7.5KW | |

| Forming thickness | 1.0mm zinc and color steel, 250Mpa-G550MPA | |

| Transmission | by single Chains 1.5inch | |

| Feeding and guide | Surface polished and coated with chrome | |

| Machine drive parts | Adopt protect cover | |

| Machine station | Adopt new station with chrome | |

| Size of main machine | 7500x1500x1300(mm) L x W x H need 1x40GP container | |

| Weight | about 8000Kgs | |

| Color of machine | Blue ( or depend on customer’s request) | |

| Machine legs | Four legs (made from metal) in 350mm |

Technological Process of IBR Corrugated Sheet / Trapezoidal Roof Panel Roll Forming Machine

De coiler—feeding—guide---roll forming----cut to length—Out table

Quick Detail

We are one of the leading suppliers and manufacturer in china and have been supplying and making roll forming equipment for the metal building construction industry for a long time.

We are Specialists in roll forming machines for the manufacture the production of building construction, such as for the metal roofing and wall, various trapezoidal profiles can be custom manufactured. We build complete roll forming lines for roofing & cladding lines.

Metal (including steel and aluminum) usage in construction is increasing more than any other building product out there. Steel roofing and steel walls are all manufactured on roll formers. Rollforming is a process by which a flat coil of steel is fed through rolls and formed to make a finished product.

Our roof panel roll forming machines are special for manufacturing high quality steel roof & wall cladding panels, aluminum Lock Roofs. With our engineer’s many times improvements, the Ribbed Roof Panels machine design is perfect. The Ribbed Roof profile surface is smooth and power fee is lower, driven by chain.

It is specially designed forming roofing corrugated sheet, wall panel,floor deck, under mass-production. The highest speed of the line can reach to 30 M/min working with fully automaticlly stacking system.

Composition of Roll Forming Machine

Roll forming main machine……………………………1 unit

Manual Un coiler……………………………………… 1 unit

Control panel…………………………………………..1 unit

Hydraulic station…………………………………… …1 unit

Manual out table……………………… ……………….2 unit

Competitive Advantage

One roll forming machine only can produce one profile.

We can manufacture as per customer provided drawings with specification or real objects of sectional materials, custom roll forming machine is welcome.

Company Introduction

Rishbin was founded in 1999. With more than ten years' development, now it becomes a leading professional supplier in the field of roll forming machinery industry, and exports its quality production

line to the markets all over the world.

We are one of the leading suppliers and manufacturer in china and have been supplying and making roll forming equipment for the metal building construction industry for a long time.

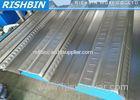

The following is some corrugated panel roofs profiles for your reference.

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

RISHBIN WUXI COMPANY [China (Mainland)]

Business Type:Manufacturer

City: Wuxi

Province/State: Jiangsu

Country/Region: China (Mainland)

You May Like:

Sitemap XML

About HiSupplier Help Center Customer Service Friend Links Site Map Archives

Browse by: China Suppliers - Hot Products - Products Directory - Offers Directory - Suppliers Directory - Buyers Directory

Language Option: العربية - Nederlands- Français- Deutsch- Italiano- 日本語- 한국의- Português- Pусский- Español